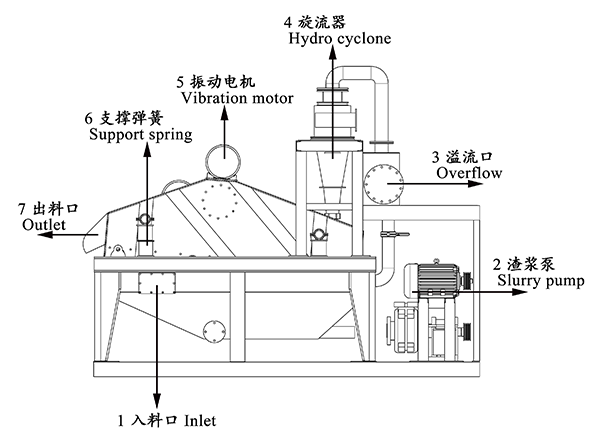

Our company has incorporated advanced international technologies and designed a state-of-the-art fine material extraction device based on the actual conditions of sand powder. This device's key feature is its ability to effectively address the problem of fine sand loss in the sand-making industry. The fine sand recovery device uses a slurry pump to inject slurry with a concentration of ≤40% into a hydrocyclone for separation. The separated coarse particles enter a dewatering screen for dewatering and recovery, maximizing the recovery of material larger than 75mm while removing sludge and clay smaller than 75mm. This minimizes fine sand loss and the resulting environmental pollution, thereby improving resource utilization.

1. Clean sand washing with high recovery rates. Secondary sand washing and dewatering of finished sand can achieve 80%-90% fine sand recovery.

2. Low cleaning costs: Fine particles are fully recovered, reducing the workload and cleaning costs of the sedimentation tank.

3. Cost and space savings: The vibrating screen combines cleaning, dewatering, and recovery functions, saving costs and space.

4. Longer life: The vibrating screen uses a polyurethane screen, which has a longer lifespan than other screen types and is non-clogging.

The BX fine sand recovery machine's main components consist of a motor, a high-pressure vacuum pump, a sediment separator, a ZKR dewatering screen, a cleaning tank, and a return tank. During operation, the pump pumps a slurry, sand, and water mixture into the sediment separator. Tailings, which have been centrifugally graded, are then fed to the dewatering screen via a sand settling nozzle. After dewatering, the tailings are effectively separated from the water. A small amount of tailings and mud are returned to the cleaning tank via the return tank. If the liquid level in the cleaning tank is too high, the sand is discharged through the discharge port. The material recovered by the dewatering screen has a weight concentration of 70%-85%. The fineness modulus can be adjusted by varying the pump speed, slurry concentration, overflow water volume, or by replacing the slurry discharge nozzle. This completes the three functions of cleaning, dewatering, and grading.

Copyright 2025 Zhengzhou Rongde Machinery Equipment Co., Ltd. Sitemap